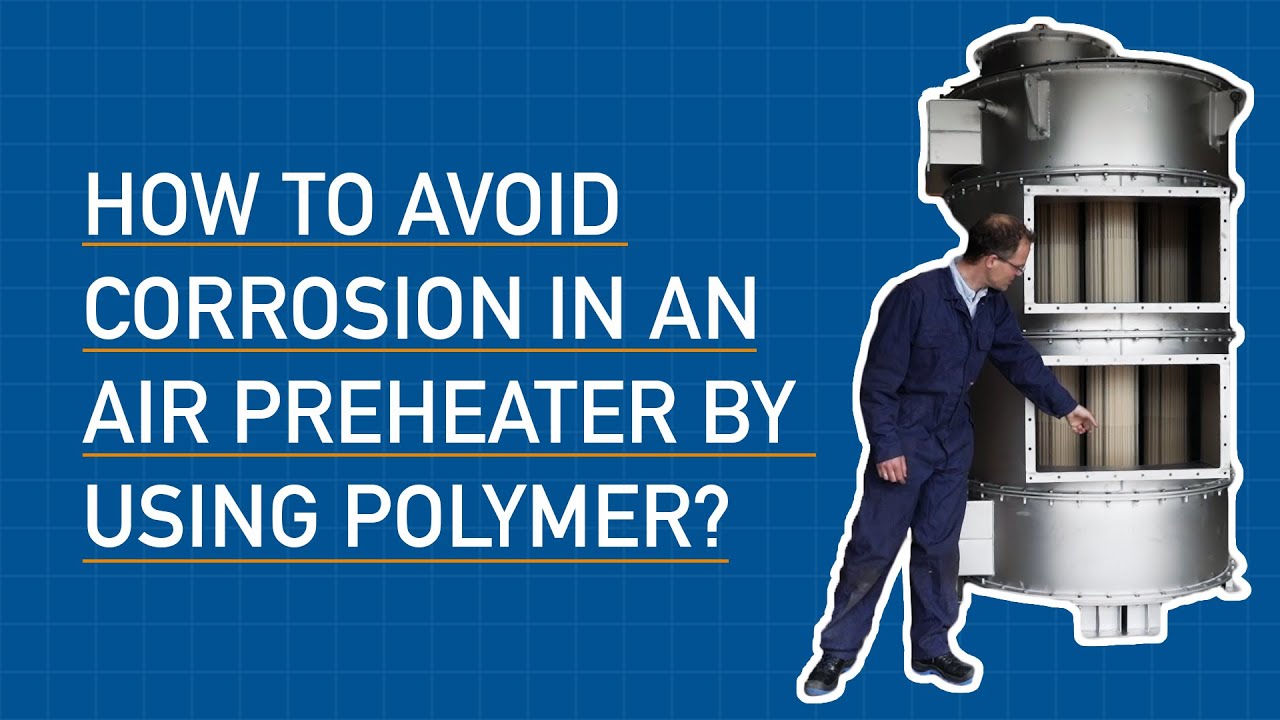

Heat Recovery Systems

For corrosive and fouling flue gas and exhaust air

Up to 20% of all heat generated by the industry is lost via flue gas or exhaust air. Concerns around corrosion and fouling often prevent industrial companies to recover additional waste heat.

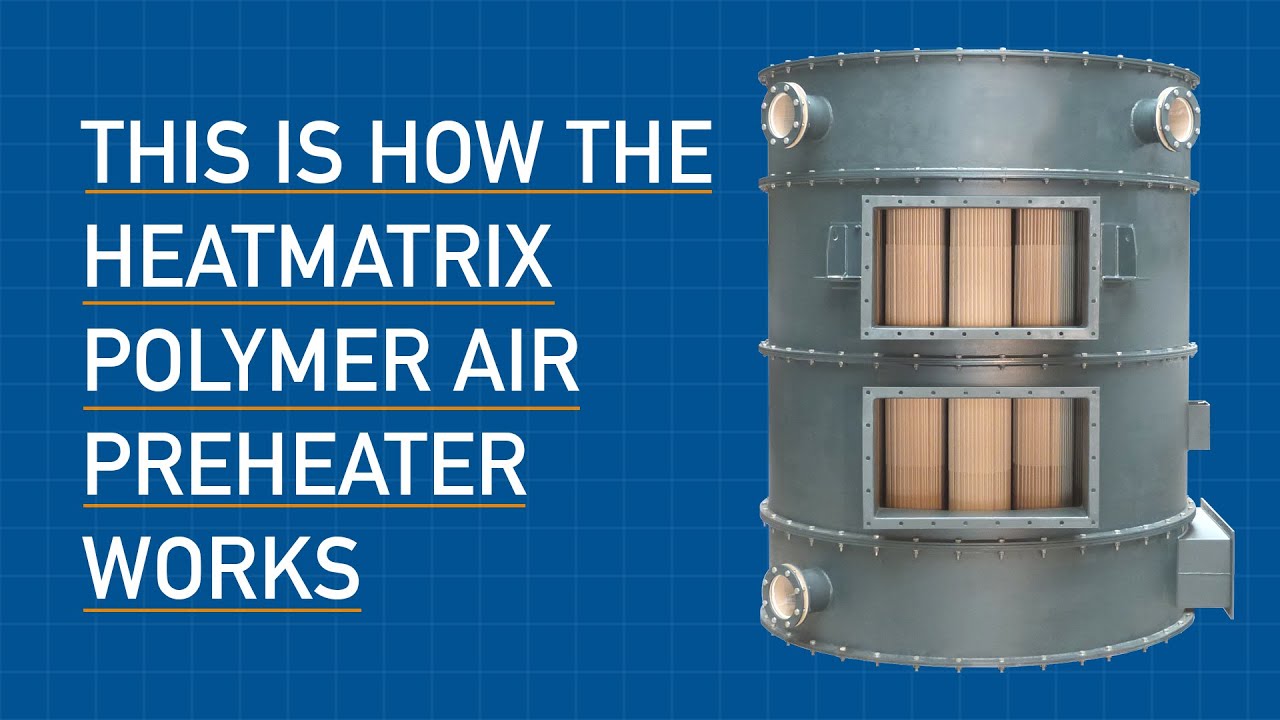

HeatMatrix Group developed heat exchangers with patented Polymer Technology, that enable heat recovery from corrosive and/or fouling flue and exhaust gases. The recovered heat can be used to warm up combustion air or water.

| Specification Title | Specification Description |

|---|---|

|

Areas of Application

|

Applicable in these industries; Oil Refining, Chemical, Beverages, Paper & Pulp, Ceramics & Bakeries.

|

|

Applicability

|

Applicable on these thermal processes; Fired Heater, Oven, Kiln, Calciner, Steam Boiler, Thermal Oil Heater, Dryer, CHP, RTO & Incinerator.

|

|

Impact

|

Reduce CO2 emissions, energy consumption & fuel costs.

|

|

Output

|

Heat up combustion air, drying air, boiler feed water, make-up water, process water or CIP water.

|

|

Return on investment

|

Less than 5 years.

|

|

Maintenance

|

No maintenance required.

|

Reviews

Sign up or log in to your explorer or platform subscription to get access to the reviews written about this technology.

The Technology Readiness Level (TRL) indicates the maturity level of novel technologies. Learn more about the TRL scale used by us.

[9/9]

Relative Business Impact

Sign up or log in to your explorer or higher plan to get access to all the 6 deployment references.

Last Deployment Year