IMS PEI – Pressure Equipment Integrity

Manage equipment integrity through RBI and advanced corrosion calculations

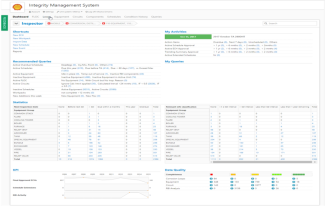

IMS PEI is a cloud-based software for Pressure Equipment Integrity.

It helps prevent leaks and explosions by improving asset availability through inspection planning. IMS PEI is part of the IMS (Integrity Management Solutions) Suite, a unified set of software solutions for all your equipment types and processes. Cenosco developed the IMS Suite in close collaboration with Shell, the multinational oil and gas leader. Today, IMS PEI has been deployed in 100+ assets, across the globe.

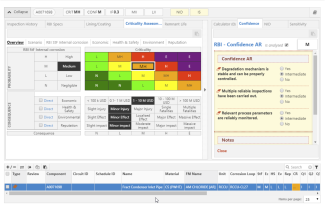

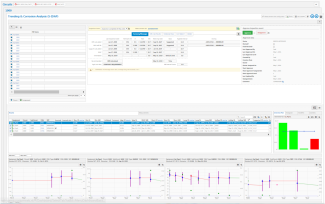

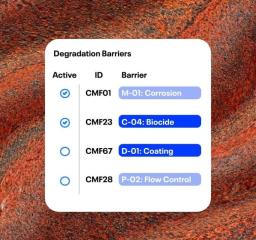

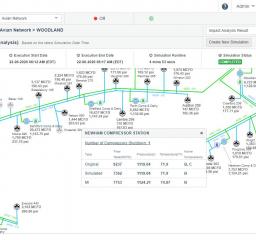

Our solution will help you manage the integrity of multiple pressure and civil equipment types used in asset-heavy industries like manufacturing and upstream businesses. IMS PEI helps you manage equipment integrity by defining 'when' and 'what' to inspect or repair using Shell's RBI methodology and advanced corrosion calculations. It will support you in defining the scope/plan for your schedule and enable you to process thickness readings faster and more accurately than ever before. This ensures that you remain compliant and auditable at all times.

The inspection intervals set in an RBI plan can be supported and reviewed using data from NII. This ensures that you also meet the requirements of a continuous risk management process. Risk-based inspection (RBI) coupled with your NII (non-intrusive inspection) data helps you improve the integrity outcomes of your pressure equipment, optimize the inspection costs, and ensure you minimize unplanned equipment downtime.

| Specification Title | Specification Description |

|---|---|

|

Certifications / licences

|

ISO 9001 | Microsoft Gold Partner | SAP Certified

|

|

Areas of Application

|

Refineries, Terminals, Tank farms, Chemical plants, Process facilities, Pulp mills, Pipelines and Wells.

|

|

Compliance

|

API 580 | Shell RBI Methodology | Auditable Events | W-IMS Platform (RCM, SIFpro)

|

|

Data Analysis

|

The data analysis part (s-IDAP) calculates alternative corrosion rates | Extreme Value Analyses for corrosion calculation | Liquid release calculators | Likelihood of failure calculators | CUI Prioritisation calculator | Bulk data statistical analysis

|

|

Hosting

|

Access your data anytime and anywhere with this web based solution. Available as shared or dedicated hosting as well as on premises – with state-of-the-art security systems.

|

|

Interface

|

Increased productivity with tailor made interfaces to your ERP systems (e.g. SAP, JDE, Maximo).

|

|

Methodology

|

The enhanced synergy of S-RBI with RCM and SIS Assessments. Qualitative method, but with quantitative parts.

|

|

Reporting

|

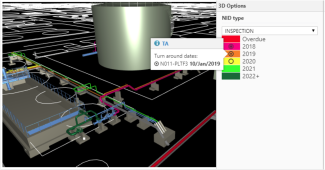

Configurable dashboards, KPIs and reporting features, including 3D visualization.

|

|

Services

|

World class support desk with over 20 years of experience | 3 releases per year, with agile development | Training – onsite and open

|

|

Usability

|

Pressured Equipment | Tanks | Flanges | Relief Devices | Civil Structures

|

Reviews (2)

Sign up or log in to your explorer or platform subscription to get access to the reviews written about this technology.

The Technology Readiness Level (TRL) indicates the maturity level of novel technologies. Learn more about the TRL scale used by us.

[9/9]

Relative Business Impact

Sign up or log in to your explorer or higher plan to get access to all the 160 deployment references.

Last Deployment Year