MONPAC

Acoustic Emission (AE) technology package for evaluating the structural integrity of metallic pressure equipment

MONPAC™ utilises proprietary multichannel AE systems and sensors that detect the high-frequency signals resulting from active defects. The systems have sufficient speed and resolution to ensure real-time, on-screen display of all activity and indications. It provides a severity grading for defects along with recommendations for further action. Sources of interest can be located on the equipment.

| Specification Title | Specification Description |

|---|---|

|

Application

|

Pressure Vessels.

|

|

Areas of Application

|

In-service pressurisation (with working fluid or inert gas) | Requalification hydrotest of used pressure equipment | First hydrotest of new pressure equipment.

|

|

Monitoring

|

Global monitoring (100% inspection, including welds, repairs etc.).

|

|

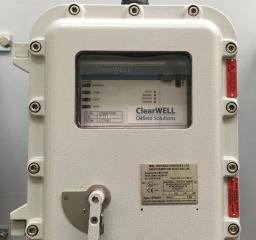

ATEX certified

|

Non applicable, working with low voltage equipment

|

|

Capabilities

|

Overstress, Manufacturing defects (e.g. weld defects), In-service defects (e.g. cracks), Corrosion, including CUI, Environmentally assisted cracking (e.g. chloride-induced SCC).

|

|

Compliance

|

Meets the requirements of ASME-V article 12, EN 15495, EN 14584 and AFIAP.

|

Reviews

Sign up or log in to your explorer or platform subscription to get access to the reviews written about this technology.

The Technology Readiness Level (TRL) indicates the maturity level of novel technologies. Learn more about the TRL scale used by us.

[9/9]

Relative Business Impact

Sign up or log in to your explorer or higher plan to get access to all the 6 deployment references.

Last Deployment Year