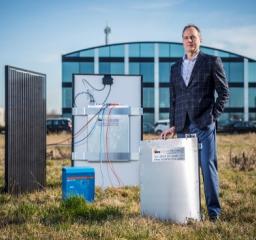

Electrochemical Hydrogen Compression and Purification (EHPC)

The new standard in hydrogen compression

Electrochemical compression of hydrogen is based on the following mechanism: hydrogen is supplied to the anode side of the membrane surface where a platinum-alloy catalyst splits the molecule into protons. The electrons are transferred via an external circuit to the catalyst layer on the opposite side of the proton exchange membrane (PEM).

HyET Hydrogen supplies complete hydrogen compression and purification units. Our modular design allows us to build units exactly tailored to customer applications. Additionally, this modularity allows for incremental capacity increases should demand for compressed and/or purified hydrogen increase over time.

| Specification Title | Specification Description |

|---|---|

|

Design

|

Modular design | More stacks = more capacity

|

|

Efficiency

|

Minimum: 2 kWh/kg | Maximum: 7 kWh/kg

|

|

Hydrogen Flow Rate

|

Minimum: 1 Nm³/hr | Maximum: 2000 Nm³/hr

|

|

Pressure

|

Input: 0.1 – 450 barg | Output: 30 – 900 barg

|

|

Size

|

19” cabinet(s) (< 20 Nm³/hr) | 10 ft container(s) (<2000 Nm³/hr)

|

|

Ambient Temperature

|

All climates

|

|

Customizability

|

Higher output pressure, alternative coolant and alternative installation areas possible.

|

Reviews

Sign up or log in to your explorer or platform subscription to get access to the reviews written about this technology.

The Technology Readiness Level (TRL) indicates the maturity level of novel technologies. Learn more about the TRL scale used by us.

[8/9]

Relative Business Impact

Sign up or log in to your explorer or higher plan to get access to all the 1 deployment references.

Last Deployment Year