Superior Sandjetting System

Efficiently fluidising solids in separators

A challenge in certain facilities is the production of solids along with the produced fluids. The reason for this may be attributable to the type of reservoir, as well as increased produced water production due to the aging of the field(s). Solids pose an issue in a production facility as they keep filling up the separators and can lead to a variety of additional issues downstream thereof. These may include damage to lines and equipment and malperformance of valves and instruments. Consequently, this may lead to process safety issues, most certainly an increased maintenance cost, as well as loss of production. It is therefore imperative to manage the solids presence in the process/facility and regularly remove the solids from the separators.

Separation of the phases

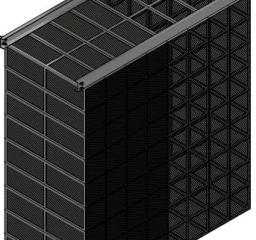

The separation of the solids from the liquid phase(s), is driven by the density difference and the particle size(s). In most separators, this takes place as the result of the gravity forces acting. Depending on the particle size distribution and the fluid flow distribution in the separator, the solids will settle from inlet to outlet. The best achievable settling performance will be achieved when the liquid flow is most evenly distributed over the wetted cross-sectional area of the vessel. As the solids accumulate, they also may leave the separator again through the liquid outlet nozzle(s) causing the downstream issues described above.

Solids removal

Therefore, once the solids have settled in the separator, they need to be removed frequently, otherwise they will accumulate to undesirable levels, impacting other separations taking place in the same volume. For that purpose, the Superior Sandjetting System can be employed.

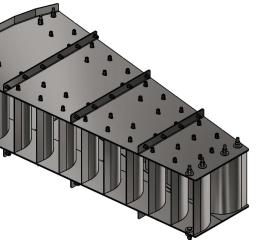

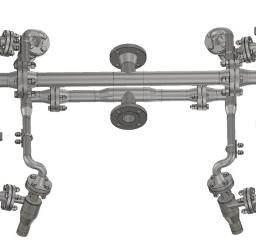

The Superior Sandjetting System operates on the principle of a certain water flow at a certain pressure being fed to the sandjetting system, which then causes the settled solids to fluidise. At the same time, separate drain nozzles will open for the slurry to leave the separator separately to the external solids handling system.

The Superior Sandjetting System is designed such that full coverage of the separator’s bottom is achieved. The system is therewith most efficient in fluidising the solids in the separator. To limit the water flow required, the system can be designed in multiple sections that can be operated in series.

| Specification Title | Specification Description |

|---|---|

|

Available sizes

|

Tailor-made to be compatible with vessel size and jetting water availability.

|

|

MOC(SS)

|

304, 316, 321, 904

|

|

MOC (Duplex)

|

S31803, S32205, S32750

|

|

MOC (Alloys)

|

C276, 400, 625, 825

|

|

MOC (Other)

|

Other materials of construction upon request.

|

Reviews

Sign up or log in to your explorer or platform subscription to get access to the reviews written about this technology.

The Technology Readiness Level (TRL) indicates the maturity level of novel technologies. Learn more about the TRL scale used by us.

[9/9]